5 Common Calibration Errors That Distort QA Accuracy

-

Bella Williams

- 10 min read

Calibration pitfalls can significantly undermine the accuracy of quality assurance efforts. In an environment where precision is paramount, even small missteps can lead to skewed results and poor decision-making. Poor calibration can affect measurement standards, leading to deviations that compromise the reliability of assessments. Understanding these pitfalls is essential for anyone involved in quality assurance, as it allows teams to identify and address potential errors before they escalate.

By recognizing the common calibration pitfalls, organizations can enhance their approaches and ensure that their QA processes yield accurate and reliable outcomes. It is crucial to consider factors such as measurement alignment and environmental influences to maintain the integrity of data. Thus, adopting a proactive mindset toward calibration not only improves QA accuracy but also fosters a culture of continuous improvement.

Analyze & Evaluate Calls. At Scale.

Understanding Calibration Pitfalls

Calibration pitfalls can significantly undermine the reliability of Quality Assurance (QA) processes. Understanding these pitfalls is crucial for maintaining consistent measurement accuracy. Many professionals encounter misalignment in measurement standards, which can stem from using different calibration methods or instruments that operate under varying conditions. This misalignment leads to discrepancies in data interpretation, impacting overall QA outcomes.

Another common pitfall is neglecting environmental factors that influence calibration results. Variations in temperature, humidity, and even electromagnetic interference can skew measurements if not properly controlled. When these aspects are overlooked, they introduce errors that compromise data integrity and reliability. Addressing these pitfalls requires a thorough understanding of both the measurement process and external variables, ensuring that calibration practices are not only accurate but also adaptable to changing conditions. By recognizing and mitigating these pitfalls, organizations can enhance their QA accuracy and improve overall operational efficiency.

1. Misalignment in Measurement Standards

Misalignment in measurement standards leads to significant challenges in ensuring accurate quality assurance (QA). When calibration methods vary across different instruments and processes, inconsistencies arise. Such discrepancies can skew data interpretation, making it difficult to achieve reliable outcomes. One common issue occurs when units of measurement differ. For instance, using imperial units when the industry standard is metric can result in errors that compromise product quality.

Another critical factor is the lack of uniform calibration protocols. Without established guidelines, each technician might apply personal methodologies, further contributing to measurement misalignment. Furthermore, inconsistency in the environment—like temperature and humidity—can distort readings, amplifying calibration pitfalls. Addressing these issues is essential for maintaining high QA accuracy. Establishing clear, standardized measurement practices will help eliminate ambiguity and foster a more reliable calibration process, ensuring products meet required specifications.

2. Neglecting Environmental Factors

Calibration processes are essential for ensuring quality assurance accuracy, yet neglecting environmental factors can lead to significant calibration pitfalls. Factors such as temperature, humidity, and vibration can drastically affect measurement outcomes. When environmental conditions fluctuate, the performance of calibration instruments may degrade, resulting in inaccurate readings. Organizations must consider these variables to maintain reliability in their quality assurance programs.

To mitigate these risks, constant monitoring of the calibration environment is crucial. First, ensure that instruments are placed in controlled environments where fluctuations are minimized. Second, regular maintenance checks should be scheduled to align equipment performance with relevant conditions. Lastly, training personnel to recognize the impact of environmental factors will empower them to maintain calibration accuracy. By incorporating these practices into standard operating procedures, organizations can effectively address calibration pitfalls and enhance overall QA accuracy.

Extract insights from interviews, calls, surveys and reviews for insights in minutes

Addressing Calibration Pitfalls

Calibration pitfalls can significantly undermine the quality assurance process. To effectively address these pitfalls, it is essential to adopt a structured approach. Begin by identifying common calibration errors. These may include misalignment between measurement standards and overlooking environmental influences that can skew results. Recognizing these errors sets the stage for implementing best practices.

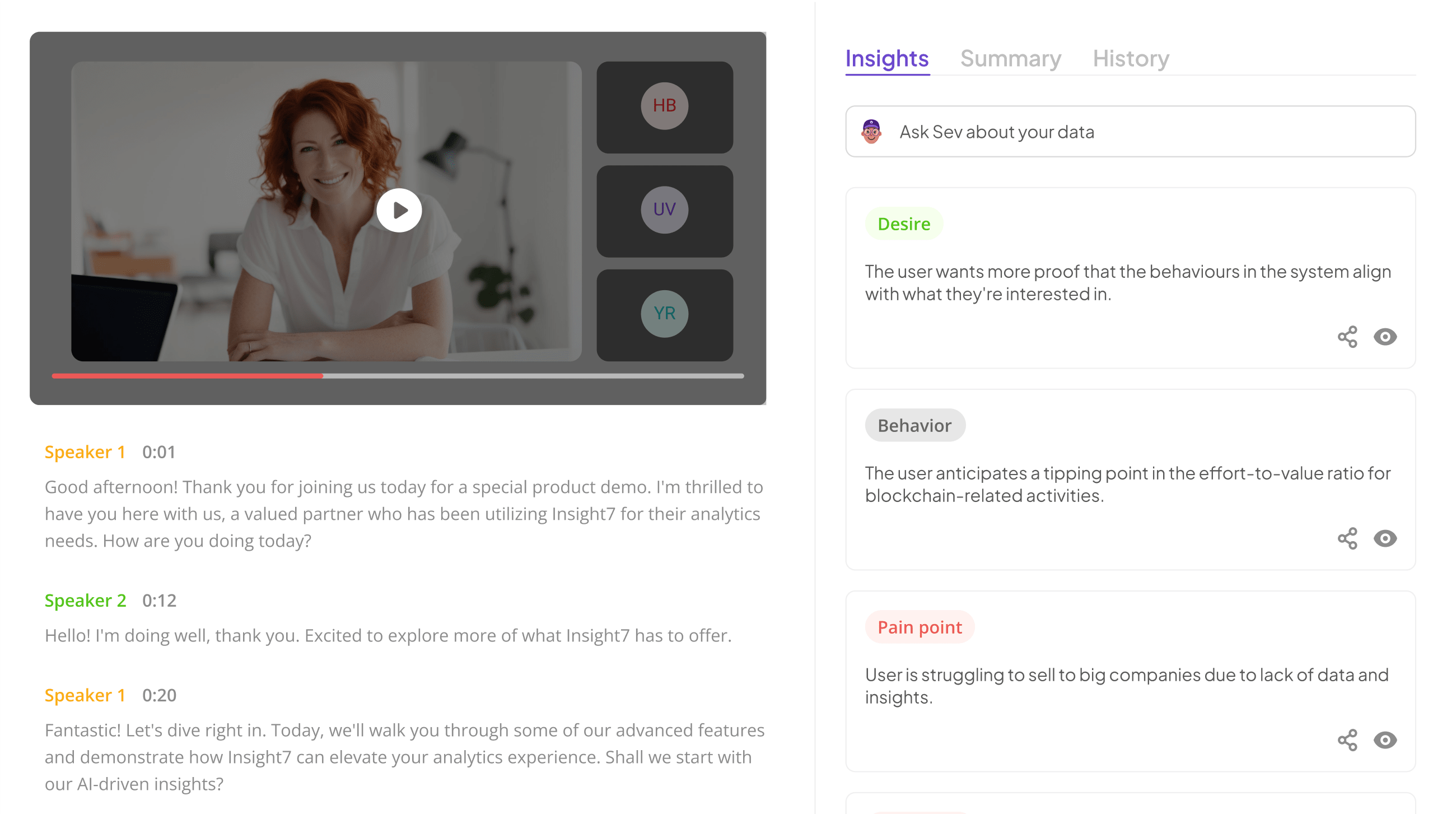

Next, utilizing the right tools is crucial for achieving accurate calibration. Solutions like insight7 and CalibrationXpert can streamline the calibration process and enhance accuracy. These tools ensure that measurements align with established standards and that variations due to environmental factors are minimized. By carefully addressing calibration pitfalls through a step-by-step methodology and appropriate tools, organizations can enhance QA accuracy and maintain reliability in their processes.

1. Step-by-Step Approach to Calibration

To effectively address calibration pitfalls, a strategic step-by-step approach is essential. First, identifying common errors is crucial. Calibration often suffers from misalignment in measurement standards, which can lead to inaccuracies. For instance, if the tools used for calibration are not standardized, the results may deviate significantly from actual measurements. Recognizing these discrepancies allows for targeted improvements.

Next, implementing best practices can help mitigate these errors. This includes regular inspection of measurement devices, ensuring they are appropriately maintained and recalibrated as necessary. Environmental factors should also be considered, as they can impact measurement outcomes. By systematically addressing these areas, organizations can enhance their quality assurance processes and achieve more reliable results. Engaging in a thorough calibration process will ultimately help identify and rectify calibration pitfalls, ensuring the accuracy needed in QA efforts.

Step 1: Identifying Common Errors

To effectively address calibration pitfalls, it's essential to identify common errors that can hinder quality assurance accuracy. The first step involves a thorough examination of the calibration process, focusing on recurring mistakes that organizations might overlook. For instance, a frequent error is the misalignment in measurement standards. This misalignment can lead to discrepancies in results, potentially distorting the evaluation of quality assurance.

Next, organizations often neglect environmental factors that play a vital role in calibration accuracy. Conditions such as temperature and humidity can significantly affect measurement readings and subsequent quality assessments. By collaborating with teams to evaluate these potential pitfalls, organizations can adopt strategies that ensure accuracy.

Identifying these common errors not only promotes a culture of precision but also empowers teams to implement corrective measures. Ultimately, recognizing calibration pitfalls is crucial for enhancing QA accuracy and achieving reliable results.

Step 2: Implementing Best Practices

Implementing best practices is essential to mitigate calibration pitfalls that can compromise QA accuracy. This process begins with detailed planning and assessment to determine the unique requirements of your calibration needs. A thorough understanding of established measurement standards ensures that all instruments are consistent and accurate. Regularly reviewing these standards helps identify any discrepancies early on, leading to prompt corrective actions.

Training staff on best practices is equally important. It exposes them to the latest calibration techniques and fosters a culture of quality assurance. Additionally, implementing regular audits and maintenance schedules helps maintain the integrity of the calibration process. Incorporating feedback mechanisms also allows for continuous improvement and adaptation to changing operational needs. By investing in these strategies, organizations can significantly reduce calibration errors and enhance overall QA accuracy, paving the way for more reliable results.

2. Utilizing Tools for Accurate Calibration

Accurate calibration is essential to ensure that measurement tools provide reliable results. Utilizing appropriate tools can significantly mitigate calibration pitfalls. For instance, software such as CalibrationXpert and MetrologyMaster can automate several calibration processes, reducing human error. Additionally, using devices like PrecisaCal can help maintain the required standards across varying environmental conditions, ensuring accurate readings consistently.

Selecting the right instrument is only the beginning; consistent monitoring is what truly enhances accuracy. Implementing regular checks with these tools allows for immediate adjustments whenever discrepancies arise. As calibration standards evolve, staying updated with the latest technology is crucial. Ultimately, embracing these tools in your calibration process will not only enhance measurement accuracy but also improve overall quality assurance efforts within your organization, minimizing errors that could distort results.

insight7

Calibration pitfalls can significantly hinder Quality Assurance (QA) accuracy, impacting your ability to deliver reliable results. It’s crucial to recognize these fallacies to mitigate errors during the calibration process. One common pitfall is misalignment in measurement standards, which can cause discrepancies in the data collected. When different teams utilize varying standards, it becomes problematic to compare results effectively, leading to misguided assessments.

Another factor to consider is neglecting environmental factors. Elements such as temperature, humidity, and electromagnetic interference can distort measurement accuracy. Ensuring that conditions remain consistent is essential for dependable calibration practices. By understanding these obstacles and their implications on QA accuracy, teams can systematically address calibration challenges. Ultimately, identifying such pitfalls will enhance the reliability of insights generated, thereby fostering informed decision-making within the organization.

CalibrationXpert

CalibrationXpert emerges as an essential tool in the realm of quality assurance. Its design focuses on mitigating common calibration pitfalls that can distort QA accuracy, ensuring that measurements are precise and reliable. Users can harness its capabilities to systematically examine and adjust measurement systems, which is vital for any organization seeking to enhance its quality assurance processes.

Utilizing CalibrationXpert allows teams to pinpoint issues such as misalignment in measurement standards and neglect of environmental factors. By adopting a methodical approach powered by CalibrationXpert, organizations can effectively tackle these calibration pitfalls. This results in improved accuracy and reliability in data, which ultimately helps maintain a high standard of quality assurance. Emphasizing the importance of consistent calibration helps teams avoid errors that could compromise product integrity and organizational performance.

PrecisaCal

In the pursuit of accurate quality assurance, focusing on PrecisaCal can greatly enhance calibration processes. This specialized tool addresses various calibration pitfalls, ensuring that measurements align with industry standards. One common calibration error arises from inadequate measurement standards, which can lead to significant inaccuracies in results. When discrepancies occur in calibration methods, they distort the integrity of data that companies rely on for decision-making.

Additionally, environmental factors play a crucial role in calibration accuracy. PrecisaCal helps users to systematically account for temperature, humidity, and other variables that could affect results. By meticulously calibrating instruments and adhering to best practices, teams can significantly reduce the likelihood of errors. Adopting such solutions not only boosts compliance with regulatory requirements but also promotes a culture of precision within organizations. Accurate calibration is not just about compliance; it’s essential for maintaining product quality and operational efficiency.

MetrologyMaster

MetrologyMaster serves as a vital cornerstone in the realm of calibration, shining a light on the calibration pitfalls that often distort QA accuracy. Understanding the intricacies of measurement standards is essential for maintaining precision in any evaluation process. With a focus on reliability, MetrologyMaster emphasizes the importance of adhering to standardized protocols to avoid misalignment, which can lead to significant errors.

Moreover, MetrologyMaster highlights the various factors influencing calibration, such as environmental conditions. Temperature swings or humidity changes can profoundly affect measurement outcomes. By addressing these calibration pitfalls proactively, organizations can reduce inaccuracies and foster a culture of quality assurance. Implementing systematic practices through tools like MetrologyMaster allows businesses to harness accurate data for better decision-making, ultimately enhancing overall product quality and compliance with industry standards.

Conclusion: Overcoming Calibration Pitfalls for Improved QA Accuracy

To overcome calibration pitfalls effectively, it is essential to instill a culture of continuous learning and adaptation within quality assurance processes. By recognizing and analyzing common errors, teams can implement best practices that enhance accuracy. Regular training and clear communication of measurement standards play crucial roles in this endeavor. Involving all team members ensures everyone understands the importance of precise calibration and its impact on overall quality.

Additionally, utilizing effective calibration tools facilitates accurate measurements, helping to reduce discrepancies. Regular audits and feedback loops can further identify areas for improvement. By addressing calibration pitfalls head-on, organizations can significantly enhance QA accuracy, leading to higher product quality and customer satisfaction.