Suppliers Evaluation Criteria for Effective Assessments

-

Bella Williams

- 10 min read

Supplier Assessment Metrics play a crucial role in ensuring a reliable evaluation of suppliers. In today’s competitive market, having a clear understanding of these metrics can significantly impact the overall performance of a business. By assessing suppliers against defined criteria, organizations can identify strengths and weaknesses, thereby making informed decisions.

Effective supplier evaluation empowers businesses to establish solid partnerships. This process not only enhances transparency but also fosters trust and collaboration among stakeholders. Utilizing well-defined assessment metrics equips companies with the tools needed to optimize supplier relationships, ultimately driving growth and success in their operations.

Generate visualizations from your qualitative data. At Scale.

Understanding Supplier Assessment Metrics: Key Criteria

Supplier Assessment Metrics form the backbone of effective evaluations in the procurement process. These metrics provide a structured way to compare potential and current suppliers based on key criteria relevant to performance and reliability. Understanding these metrics is crucial for organizations aiming to ensure they partner with vendors who can consistently deliver quality products or services.

Key criteria for assessment often include quality of goods, pricing competitiveness, delivery performance, and customer service responsiveness. Each of these factors plays an essential role in evaluating a supplier’s capability to meet business needs. For instance, quality metrics can gauge defects or compliance rates, while pricing competitiveness can highlight a supplier’s value proposition. By systematically analyzing these metrics, organizations can make informed decisions that enhance operational efficiency and foster long-term supplier relationships. Choosing the right criteria leads to better supplier selection, ultimately driving organizational success.

Reliability and Consistency

When assessing suppliers, reliability and consistency play a crucial role in Supplier Assessment Metrics. Reliability involves the supplier’s ability to deliver products or services consistently within agreed timelines, while consistency refers to maintaining quality and performance over time. A reliable supplier is one who minimizes disruptions, ensuring that operations run smoothly and efficiently.

Key metrics to evaluate these attributes include on-time delivery rates, the frequency of order discrepancies, and quality control measures. A supplier demonstrating high on-time delivery rates shows that they are dependable, while a low rate of order discrepancies indicates a strong commitment to consistency. Additionally, regular quality assessments will highlight any variations in the product or service quality, informing the evaluation process. Together, these metrics provide a comprehensive view of a supplier’s reliability and consistency, which are essential for fostering long-term business relationships.

Quality and Compliance

Quality and compliance are essential components in evaluating suppliers. High-quality standards ensure that products meet the required specifications and effectively serve the intended purpose. Compliance, on the other hand, refers to adherence to regulatory and industry standards that safeguard both the business and its customers. Together, they form the backbone of Supplier Assessment Metrics, guiding organizations in their decision-making process.

When evaluating suppliers, consider these key factors: first, assess the supplier’s quality control processes to ensure consistency in their output. Next, verify their compliance with relevant standards and regulations to mitigate risks associated with non-compliance. Additionally, evaluate feedback and performance data to gauge reliability and responsiveness. Understanding these elements not only streamlines procurement but also fosters long-term partnerships with suppliers who align with your values. Ultimately, prioritizing quality and compliance leads to enhanced operational efficiency and improved customer satisfaction.

Evaluate Performance on Customer Calls for Quality Assurance.

Evaluating Supplier Assessment Metrics: Processes and Tools

Evaluating Supplier Assessment Metrics involves a systematic approach to ensure effective assessments of suppliers. This process typically includes identifying key performance indicators (KPIs) that reflect not only the suppliers’ capabilities but also their alignment with organizational values. Understanding these metrics allows organizations to track supplier performance over time, strengthening their supply chain relationships.

Several critical processes can be used to evaluate Supplier Assessment Metrics effectively. First, establishing clear evaluation criteria ensures consistency and transparency during supplier assessments. Next, using scoring systems provides a quantifiable method to compare suppliers objectively. Additionally, incorporating regular feedback and reviews enhances the understanding of supplier performance. Lastly, utilizing technology tools can streamline the evaluation process, making data gathering more efficient and accessible. By harnessing these methods, organizations can make informed decisions that promote collaboration and drive mutual success within their supply chains.

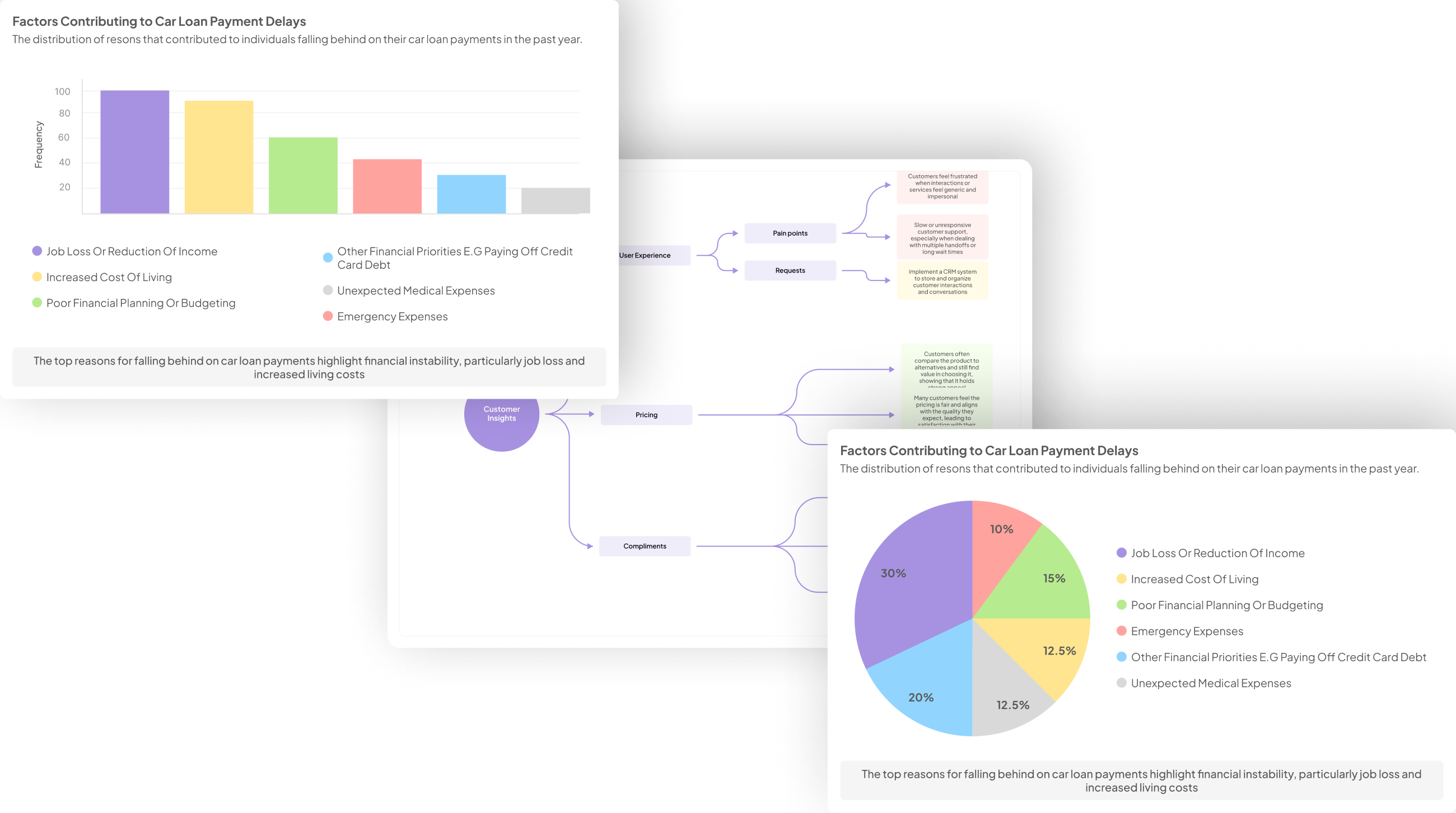

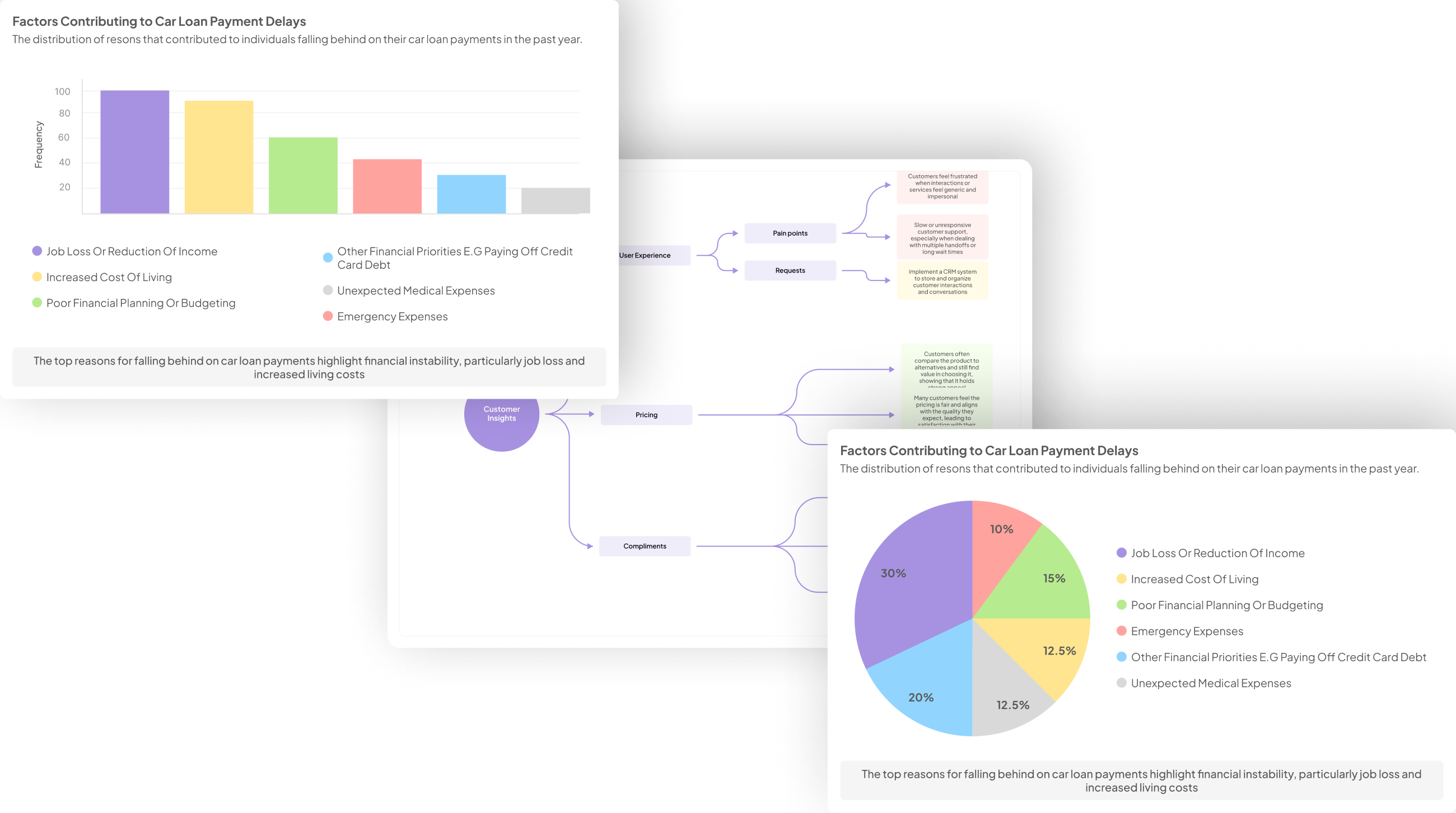

Performance Tracking and Data Analysis

Performance tracking is essential for maintaining effective supplier relationships. Regular assessment allows organizations to monitor Supplier Assessment Metrics, providing insights into performance consistency over time. Tracking these metrics enables a clear view of suppliers’ operational effectiveness and their alignment with organizational goals.

Data analysis complements performance tracking by offering a detailed breakdown of the collected data. By analyzing trends and patterns, businesses can identify top-performing suppliers and those needing improvement. Key focus areas might include on-time delivery rates, quality of products or services, and responsiveness to communication. This quantitative and qualitative evaluation fosters informed decision-making, leading to stronger partnerships and enhanced supply chain efficiency. Continuous tracking and thorough data analysis ultimately support a proactive rather than reactive approach to supplier management.

Risk Management and Mitigation

Effective Risk Management and Mitigation is crucial in supplier evaluation, where Supplier Assessment Metrics guide decisions. Identifying potential risks helps organizations make informed choices that align with their goals. A comprehensive approach involves assessing suppliers based on quality, reliability, and compliance to minimize vulnerabilities.

There are several key aspects to consider in risk management. First, evaluate a supplier’s financial stability to prevent disruptions due to insolvency. Second, scrutinize their compliance with industry standards to mitigate legal risks. Third, review their supply chain practices to ensure resilience against unforeseen challenges. Lastly, consider the supplier’s track record in delivering consistent quality and timely services.

Addressing these factors allows for a proactive stance on risk. By integrating effective Supplier Assessment Metrics, organizations can enhance their decision-making process, ensuring sustainability and efficiency in supplier relationships. A well-rounded supplier evaluation framework ultimately fosters a reliable supply chain.

Conclusion: The Future of Supplier Assessment Metrics in Business Strategy

The future of supplier assessment metrics in business strategy promises significant advancements as organizations increasingly prioritize reliable evaluation methods. Implementing versatile and responsive supplier assessment metrics will be essential for adapting to shifting market dynamics. Businesses must embrace a comprehensive approach that integrates qualitative insights with quantitative data to enhance supplier relationships and drive growth.

Generate visualizations from your qualitative data. At Scale.

As supplier assessment metrics evolve, companies will need to focus on integrating technology and data analytics into their processes. This integration will not only streamline evaluations but also provide deeper insights into supplier performance. Looking ahead, fostering collaboration and open communication between businesses and suppliers will be imperative for crafting a successful partnership environment.